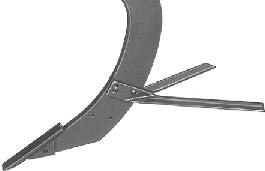

22B INTEGRAL RIPPER

Integral Ripper

- Regular and capped ripper points

- LaserRip™ Extreme points

- Mole ball is used to make a tunnel drainage system

- Heavy-duty knife

View Product Brochure

Features

A single parabolic standard ripper provides an economical means of shattering hardpan soil by exploding the soil upward to promote root growth:

- Curved standard is less likely to slice through marginally moist soils than a straight standard

- Mole ball can be attached to the standard to help drain wet soils by leaving a small tunnel under the soil

- V-knife can be attached to the standard to effectively cut the root systems

- Improves water percolation into the subsoil zone

Two sizes of standards are available:

- 25 mm x 686 mm (1 in. x 27 in.)

- Maximum working depth of 406 mm (16 in.)

- 32 mm x 838 mm (1.25 in. x 33 in.)

- Maximum working depth of 559 mm (22 in.)

Both standards are protected for up to 6364 kg (14,000 lb) of operating force by a 16-mm (5/8-in.) shear bolt.

The 22B In-Line Ripper attaches to the tractor's 3-point hitch:

- 25-mm x 686-mm (1-in. x 27-in.) standard model is compatible with Category 1, 3-point hitch tractors.

- 32 mm x 838 mm (1.25 in. x 33-in.) standard model is compatible with Category 2 or 2/3N tractors with or without Quik-Coupler

- 16.9-30 or larger rear tractor tires are recommended

Specifications

| Key Specs | 22b-integral-ripper Current Model |

|---|---|

| Working width | |

| Transport width | |

| Operating depth | Maximum 406 to 559 mm 16 to 22 in. |

| Miles per hour | |

| Horsepower per standard | With 3-point hitch: 53 to 165 engine kW 39.5 to 123 engine hp |

| Spacings | |

| Tool configuration | |

| Type | V-ripper |

| Option 1 | Integral ripper |

| Option 2 | |

| Option 3 | |

| Option 4 | |

| Option 5 | |

| Option 6 | |

| Option 7 | |

| Option 8 | |

| Option 9 | |

| Option 10 | |

| Option 11 | |

| Option 12 | |

| Option 13 | |

| Option 14 | |

| Option 15 | |

| Option 16 | |

| Option 17 | |

| Option 18 | |

| Option 19 | |

| Option 20 | |

| Option 21 | |

| Option 22 | |

| Working width | |

| Option 1 | |

| Option 2 | |

| Option 3 | |

| Option 4 | |

| Option 5 | |

| Option 6 | |

| Option 7 | |

| Option 8 | |

| Option 9 | |

| Option 10 | |

| Option 11 | |

| Option 12 | |

| Option 13 | |

| Option 14 | |

| Option 15 | |

| Option 16 | |

| Option 17 | |

| Option 18 | |

| Option 19 | |

| Option 20 | |

| Option 21 | |

| Option 22 | |

| Transport width | |

| Option 1 | |

| Option 2 | |

| Option 3 | |

| Option 4 | |

| Option 5 | |

| Option 6 | |

| Option 7 | |

| Option 8 | |

| Option 9 | |

| Option 10 | |

| Option 11 | |

| Option 12 | |

| Option 13 | |

| Option 14 | |

| Option 15 | |

| Option 16 | |

| Option 17 | |

| Option 18 | |

| Option 19 | |

| Option 20 | |

| Option 21 | |

| Option 22 | |

| Operating depth | |

| Maximum | 406 to 559 mm 16 to 22 in. |

| Frame | |

| Size | |

| Maximum underframe clearance | |

| Operating speed | |

| Miles per hour | |

| Horsepower required | |

| Horsepower per standard | With 3-point hitch: 53 to 165 engine kW 39.5 to 123 engine hp |

| Depth control | |

| Option 1 | |

| Option 2 | |

| Option 3 | |

| Hydraulic requirements | |

| Option 1 | |

| Option 2 | |

| Hitch | |

| Options | |

| Three-point hitch requirements | Category 1, 2, or 3/N without Quik-Coupler for standard: 686 mm 27 in. Category 2 or 2/3N with or without Quik-Coupler for standard: 838 mm 33 in. 16.9-30 or larger rear tractor tires are recommended |

| Pull-type description | |

| Standard options | |

| Spacings | |

| Option 1 | Standard type Parabolic Standard: 32x686 mm 1.25x27 in. Penetration: 406 mm 16 in. |

| Option 2 | Standard type Parabolic Optional: 32x838 mm 1.25x33 in. Penetration: 559 mm 22 in. |

| Option 3 | |

| Option 4 | |

| Coulters | |

| Description | |

| Type | |

| Pounds of force | |

| Blades | High-carbon steel: 76x10 mm 3x0.375 in. Long: 610 mm 24 in. |

| Closing wheel attachment | |

| Description | |

| Down force | |

| Size | |

| Spacing | |

| Angle adjustments | |

| Stabilizer/gauge wheels | |

| Type | |

| Wheels | |

| Tires | |

| Pull-type wheels | |

| Description | |

| Additional feature | |

| Option 1 | |

| Option 2 | |

| Option 3 | |

| Option 4 | |

| Ground-engaging components | |

| Options |

Accessories and Attachments

Hitch

For Category 2 and 2/3N Tractors with Quik-Coupler, order AR27093.

For Category 2/3N Tractors without Quik-Coupler, order one R64434 and two R66435.

For Category 2 and 2/3N Tractors with Quik-Coupler, order AR27093.

For Category 2/3N Tractors without Quik-Coupler, order one R64434 and two R66435.

Standards

Standards may be ordered to convert the machine for different operational requirements. In the sales manual, see tractor compatibility and equipment requirements for restrictions.

To convert from a 25-mm x 686-mm (1-in. x 27-in.) standard to a 32-mm x 838-mm (1.25-in. x 33-in.) standard, order N261789.

To convert from a 32-mm x 838-mm (1.25-in. x 33-in.) standard to a 25-mm x 686-mm (1-in. x 27-in.) standard, order N261788 and A25273.

Standards may be ordered to convert the machine for different operational requirements. In the sales manual, see tractor compatibility and equipment requirements for restrictions.

To convert from a 25-mm x 686-mm (1-in. x 27-in.) standard to a 32-mm x 838-mm (1.25-in. x 33-in.) standard, order N261789.

To convert from a 32-mm x 838-mm (1.25-in. x 33-in.) standard to a 25-mm x 686-mm (1-in. x 27-in.) standard, order N261788 and A25273.

Standards Attachments

Heavy-duty knife

Heavy-duty knifeThe heavy-duty knife attaches to the lower end of the standard to open up the sub-soil and shear the roots.

Each knife is 610 mm (24 in.) long and will cut 267 mm (10.5 in.) on each side of the standard.

The 76-mm x 8-mm (3-in. x 5/16-in.) blades are sharpened on the leading edge.

Mole ball

Mole ballThe mole ball is used to make a tunnel drainage system. It requires BA24894 standard support attachment.

Standard support attachment

Standard support attachmentThe standard support attachment is required to attach the mole ball to the standard. It also allows the frame to jackknife for automatic retraction and operation of the standard.