460M MEGAWIDEHC ROUND BALER

MegaWide™ HC² Round Baler

- MegaWide™ HC² feed system with Precutter

- BaleTrak™ Pro monitor-controller

- Exclusive DiamondTough™ triple weave belts

- Exclusive COVER-EDGE™ surface wrap option

View Product Brochure

Features

Specifications

Compare the specifications of up to 4 models

| Key Specs | 460m-megawidehc-round-baler Current Model |

|---|---|

| Belts-other - width | 17.8 cm 7 in. |

| Density control | Hydraulic |

| Bale size indication | Electronic display on monitor |

| Regular pickup - Bars | |

| Regular pickup - Number of teeth | |

| Regular pickup - Tooth spacing | |

| MegaWide Plus pickup - Number of regular teeth | 96 |

| MegaWide Plus pickup - Number of mega teeth | 16 |

| High-capacity pickup - Number of middle teeth | 120 |

| High-capacity pickup - Number of mega teeth | Eight |

| Bale | |

| Size | Diameter 81 - 183 cm 32 - 72 in. Width 117 cm 46 in. 1.2 x 1.8 m 4 x 6 ft |

| Weight | Full-size bale in dry crop 748 kg 1,650 lb Max. allowable for silage bale 998 kg 2,200 lb |

| Baler | |

| Base weight | |

| Weight | Shipping dry - 2,800 kg 6,172 lb Shipping silage - 2,979 kg 6,568 lb Shipping precutter - 3,930 kg 8,665 lb |

| Length | Gate closed 371 cm 146 in. Gate open 475 cm 187 in. |

| Height | Gate closed 279 cm 110 in. Gate open 368 cm 145 in. |

| Width | With standard tires 226 cm 89 in. With opt. tires (Hi-Flotation) 244 cm 96 in. |

| Bale forming | |

| Forming chamber | |

| Belts-other | Number Six Width 17.8 cm 7 in. Texture Diamond Tread friction surface belts DiamondTough, triple-weave, single-ply belts |

| Enclosed percent of bale surface | |

| Belt splices | |

| Density control | Hydraulic |

| Bale size indication | Electronic display on monitor |

| Bale Shape | |

| Regular pickup | |

| Type | |

| Width | |

| Drive | |

| Bars | |

| Number of teeth | |

| Tooth spacing | |

| Lift control | |

| Gauge wheels | |

| Stripper diameter | |

| MegaWide Plus pickup | |

| Type | |

| Width | Inside 155 cm 61 in. Flare 180 cm 71 in. |

| Drive | |

| Bars | |

| Number of regular teeth | 96 |

| Number of mega teeth | 16 |

| Tooth spacing | |

| Lift control | |

| Gauge wheels | Semi-pneumatic |

| Stripper diameter | |

| High-capacity pickup | |

| Type | MegaWide High Capacity and Cutting (HC |

| Width | Inside 196 cm 77 in. Flare 221 cm 87 in. |

| Drive | |

| Bars | |

| Number of middle teeth | 120 |

| Number of mega teeth | Eight |

| Tooth spacing | |

| Lift control | |

| Gauge wheels | Semi-pneumatic |

| Stripper diameter | 25.4 cm 10 in. |

| Wrapping system | |

| Control | Automatic to preset to bale size |

| Type | Standard Electric |

| Twine arms | Two |

| Twine ball capacity | Eight |

| Monitor | |

| Monitor console for tractor | |

| Gate closed | Symbol on monitor |

| Bale forming | BaleTrak Pro |

| Bale size | Mechanical and digital |

| Near full bale | Audible, adjustable alert |

| Full bale | Audible, adjustable alert |

| Twine arm position Indicator | Mechanical |

| Auto wrap | Activates when bale reaches preset size |

| Oversize bale | Yes, audible and mechanical alerts |

| Surface wrap | |

| Available | |

| Tire size | |

| Standard | Dry and Silage - high-flotation 14 L - 16.4, 8 PR |

| Optional | With MegaWide Plus or MegaWide HC |

| Driveline | |

| Drive protection | Slip clutch |

| PTO speed | 540 rpm |

| Type | Constant-velocity (CV) |

| PTO lockback collar on tractor hookup | Yes |

| PTO 60-degree free rotation | Yes |

| Tractor Requirements | |

| Minimum PTO | Dry Hay and Silage - 48 kW 65 hp MegaWide HC kW 85 hp |

| Hydraulic SCV valves | One tractor selective control valve (SCV) is required when baler is equipped with electric twine wrap. Two tractor SCVs are required when baler is equipped with hydraulic twine wrap. Three tractor SCVs are required when baler is equipped with hydraulic twine wrap and a hydraulic pickup lift. |

| Silage baler features | |

| Starter roll scraper | |

| Powered scraping auger | |

| Spirals on gate roll | |

| Pre-cutter/slicer |

Accessories and Attachments

Bale Ejection

Hydraulic bale ramp

Hydraulic bale ramp

Hydraulically operated bale ramps are available as optional equipment on 459, 459 Standard, 459 Silage Special, 559 Silage Special, and 559 Round Balers.

- Allows a bale to roll away from the baler

- Eliminates the operator having to back up to eject the bale on level or moderately rolling terrain

NOTE: The tractor must have a 2200-psi hydraulic system to operate hydraulic bale ramps.

Take up arms - BE32453

Baler Isobus Compatibility

Crop Deflector Kits

Crop deflector kit

Crop deflector kit

The crop deflector kit prevents crop accumulation in the lower gate area of the baler that can keep the gate from closing. The deflector keeps crop out of the lower gate area as the bale is ejected from the bale chamber.

- Standard equipment on 457, 557, 467, and 567 Balers ordered with the regular (code 3000) or MegaTooth™ (code 3010) pickup AND the COVER-EDGE™ surface wrap (code 5500) serial numbers 320001 and above.

- Can be field installed on any 7 Series Round Baler. Order as an attachment for field conversion.

- Recommended for operators who bale cornstalks or other dry, brittle crops.

Density Control

Variable core for balers with BaleWatch

Variable core for balers with BaleWatchThis variable core kit is for 457, 457 Silage Special, and 557 Balers equipped with the BaleWatch™ monitor.

Variable core for BaleTrak Plus or BaleTrak Pro

Variable core for BaleTrak Plus or BaleTrak ProThis variable core kit is for 67 Series Balers and 57 Series Balers equipped with the BaleTrak™ Pro and BaleTrak Plus monitor-controller.

This kit reduces hydraulic pressure for easier bale starts in difficult conditions.

- Reduces core density

- Adjustable soft core diameter to within 4 in. of the bale's outer diameter

- Controlled and adjusted from the BaleTrak Pro monitor-controller and BaleTrak Plus monitor-controller on 457 Silage Special, 457, 557, 466 Silage Special, 466, and 566 Round Balers

- Connects to a three-terminal convenience outlet on 457, 457 Silage Special, and 557 Round Balers, if equipped with an optional hydraulic tie and a BaleWatch monitor

Displays

Auxiliary International Standard Organization (ISO) Bus Harness - BE32278

BaleTrak Pro monitor-controller

BaleTrak Pro monitor-controllerA second BaleTrak Pro monitor-controller and tractor portion of the wiring harness can be ordered for installation on a second tractor, if desired:

- For 458, 458 Standard with automatic electric tie, 458 Silage Special, 558, 468, 468 Silage Special, and 568 Round Balers

Override switch

Override switchA manual twine-arm override switch (A) is included with the monitor wiring.

The switch allows the operator to manually wrap twine on the bale if the BaleTrak Pro monitor-controller malfunctions.

NOTES:

- For tractors not equipped with a convenience outlet, order AE50549 three-terminal convenience outlet wiring harness from Parts. Do not convert to a two-terminal outlet.

- Console mounting requires additional parts:

- For 6000, 6010, 6020, 6030, 7000, 7010, 7020, 7030, 8000, 8010, 8020, and 8030 Series Tractors with a cab, order BE23519 console mounting bracket.

- For open station 6000 Series Tractors (serial numbers 148721 and below) and all 7000, 7010, 7020, and 7030 Series Tractors, order BE23840 mounting kit.

- For 6405, 6605, and 7405 Advantage Series Tractors, and 6015 and 6003 Open-Station Tractors, order BE23963.

- For 6000, 6010, 6020, 6030 Series Tractors and open-station John Deere 6000 Series Tractors (standard on 6000 Series Tractors with serial numbers 148722 and above or low-profile 6000 Series Tractors with serial numbers 148787 and above), order BE23862 mounting kit.

- For John Deere tractors with a SoundGard body, order BE23599 console mounting bracket.

- For 5000, 5010, 5020, and 5025 Series Open-Station Tractors (only with the straddle mount station on the 5020), order BE23861 mounting kit.

- For 5000 and 5010 Series Tractors with a cab, order BE23864 mounting kit.

- For 5020 and 5025 Series Tractors with the optional isolated open operator station, order BE24231.

These parts are required to install the electric twine-wrap control module on the tractor for 447 and 547 Round Balers.

For 5000, 5010, 5020, 5025, 6000, 6010, 6015, 6020, 6005, 7000, 7010, 8000, 8010, 8020 Cab Tractors

A54171 and A53254

A54171 and A53254A54171 and A53254 are for 447 and 547 Round Balers with the optional electric twine module.

For 5000, 5010, 5020, 5025, 6000, 6010, 6015, 6020, 6005, 7005, and 6003 Open-Station Tractors

BE23863

BE23863BE23863 is required to mount the electric twine control module on open-station tractor rollover protective structures (ROPS) for 447 and 547 Round Balers.

In addition to this bundle, the following brackets and hardware must be ordered through Parts.

For the electric twine control module, also order A54171 and A53254

For John Deere Tractors with a Sound-Gard body

E88560

E88560E88560 is for the electric twine control module for the 447 and 547 Round Balers.

These parts are required to install the electric twine-wrap control module on the tractor for 447 and 547 Round Balers.

For 5000, 5010, 5020, 5025, 6000, 6010, 6015, 6020, 6005, 7000, 7010, 8000, 8010, 8020 Cab Tractors

A54171 and A53254

A54171 and A53254A54171 and A53254 are for 447 and 547 Round Balers with the optional electric twine module.

For 5000, 5010, 5020, 5025, 6000, 6010, 6015, 6020, 6005, 7005, and 6003 Open-Station Tractors

BE23863

BE23863BE23863 is required to mount the electric twine control module on open-station tractor rollover protective structures (ROPS) for 447 and 547 Round Balers.

In addition to this bundle, the following brackets and hardware must be ordered through Parts.

For the electric twine control module, also order A54171 and A53254

For John Deere Tractors with a Sound-Gard body

E88560

E88560E88560 is for the electric twine control module for the 447 and 547 Round Balers.

These parts are required to install the electric twine-wrap control module on the tractor for 447 and 547 Round Balers.

For 5000, 5010, 5020, 5025, 6000, 6010, 6015, 6020, 6005, 7000, 7010, 8000, 8010, 8020 Cab Tractors

A54171 and A53254

A54171 and A53254A54171 and A53254 are for 447 and 547 Round Balers with the optional electric twine module.

For 5000, 5010, 5020, 5025, 6000, 6010, 6015, 6020, 6005, 7005, and 6003 Open-Station Tractors

BE23863

BE23863BE23863 is required to mount the electric twine control module on open-station tractor rollover protective structures (ROPS) for 447 and 547 Round Balers.

In addition to this bundle, the following brackets and hardware must be ordered through Parts.

For the electric twine control module, also order A54171 and A53254

For John Deere Tractors with a Sound-Gard body

E88560

E88560E88560 is for the electric twine control module for the 447 and 547 Round Balers.

These parts are required to install the electric twine-wrap control module on the tractor for 447 and 547 Round Balers.

For 5000, 5010, 5020, 5025, 6000, 6010, 6015, 6020, 6005, 7000, 7010, 8000, 8010, 8020 Cab Tractors

A54171 and A53254

A54171 and A53254A54171 and A53254 are for 447 and 547 Round Balers with the optional electric twine module.

For 5000, 5010, 5020, 5025, 6000, 6010, 6015, 6020, 6005, 7005, and 6003 Open-Station Tractors

BE23863

BE23863BE23863 is required to mount the electric twine control module on open-station tractor rollover protective structures (ROPS) for 447 and 547 Round Balers.

In addition to this bundle, the following brackets and hardware must be ordered through Parts.

For the electric twine control module, also order A54171 and A53254

For John Deere Tractors with a Sound-Gard body

E88560

E88560E88560 is for the electric twine control module for the 447 and 547 Round Balers.

Order the following mounting bracket bundles to install BaleTrak Pro monitors in tractors with or without cabs.

Order the following mounting bracket bundles to install BaleTrak Pro monitors in tractors with or without cabs.

Order the following mounting bracket bundles to install BaleTrak Pro monitors in tractors with or without cabs.

Order the following mounting bracket bundles to install BaleTrak Pro monitors in tractors with or without cabs.

Order the following mounting bracket bundles to install BaleTrak Pro monitors in tractors with or without cabs.

Order the following mounting bracket bundles to install BaleTrak Pro monitors in tractors with or without cabs.

Order the following mounting bracket bundles to install BaleTrak Pro monitors in tractors with or without cabs.

Slip Clutch Alert and Automatic Compensation - BE32317

Slip clutch alert and automatic compensation - BE32327

Drawbar

Drawbar Dropdown - AL81724

Drawbar Dropdown - RE63147

Drawbar

Drawbar shield

Drawbar shieldA drawbar shield helps to prevent windrow bunching that can occur when the drawbar contacts heavy windrows.

Fire Extinguisher

Fire extinguisher

Fire extinguisherA pressurized 2-1/2 U.S. gal. (9.5-L) water-type fire extinguisher can be installed on the baler.

It is recommended for hay and grass fires.

Fire Extinguisher Mounting Bracket - AFH207443

Fire extinguisher

Fire extinguisherA pressurized 2-1/2 U.S. gal. (9.5-L) water-type fire extinguisher can be installed on the baler.

It is recommended for hay and grass fires.

Gauge Wheels

Complete Gauge Wheels, Arms, Hardware and decal for MegaWide Plus pickups - BE32712

Gauge Wheel and Tire for Regular, MegaWide Plus and MegaWide HC2 Pickup - BE31132

Harnesses

Seven-pin outlet kit

Seven-pin outlet kitThe seven-terminal electrical outlet is required on tractors not equipped to power the taillights and turn signals.

Convenience outlet kit

Convenience outlet kitThis convenience outlet and wiring harness can be installed in a tractor without a convenience outlet to power the monitor.

The harness is recommended for use with either the optional BaleWatch™ monitor on 457, 457 Silage Special, and 557 Round Balers, or with the BaleTrak™ Pro and BaleTrak Plus monitor-controller on 457, 457 Silage Special, 557, 467 Silage Special, 467, and 567 Round Balers.

Adapter

AdapterThis wiring harness is required to hook up electric controls with a three-terminal plug to a tractor with a two-terminal convenience outlet.

The harness is recommended to be used only with the BaleWatch™ monitor on 457, 457 Silage Special, and 557 Round Balers.

IMPORTANT: Do not use this harness with the BaleTrak™ Pro or BaleTrak Plus monitor-controller. A voltage drop may occur, resulting in lower force from the twine and surface-wrap accuators.

Harness, Convenience Outlet - AE50531

Hitches

625 Mower-Conditioner illustrated

625 Mower-Conditioner illustratedA safety chain serves as a device to ensure the mower-conditioner stays attached to the tractor, should a drawbar or hitch pin failure occur.

The tractor must be equipped with an intermediate chain support ahead of the hitch pin.

Hydraulic Pickup Lift

Hydraulics

Pressure reduction kit

Pressure reduction kitThe hydraulic pressure reduction kit is required when 435 ( -969343) and 535 ( -971693) Round Balers, equipped with a push bar, are used with a John Deere 6000 and 7000 Series Tractor or competitive tractor with hydraulic system pressure above 2500 psi.

It reduces the potential for damage to the gate cylinders due to high-pressure spikes when opening the gate on balers equipped with a push bar.

Knives

14 KNIFE BUNDLE REPLACEMENTS - BE32686

21 KNIFE BUNDLE REPLACEMENTS - BE32685

Miscellaneous

Adjustable twine guide

Adjustable twine guideAdjustable twine guides are used to move the location of the twine closer to the center of the bale.

- Especially useful when baling slick grasses and straw

- One left-hand adjustable twine guide is available for the 447, 457, and 457 Silage Special Balers

- Both a left-hand and right-hand adjustable twine guide are available for the 547 and 557 Balers

Auxiliary take-up rolls eliminate flipping and twisting of the belts in hilly conditions.

- Attachment BE32258 is available for the 469 and 469 Premium Balers.

- Attachment BE32259 is available for the 569 and 569 Premium Balers.

Base Equipment: All silage special round balers.

Auxiliary take-up rolls eliminate flipping and twisting of the belts in hilly conditions.

- Attachment BE32258 is available for the 469 and 469 Premium Balers.

- Attachment BE32259 is available for the 569 and 569 Premium Balers.

Base Equipment: All silage special round balers.

Bale counter - BE22696

Bale ramp - BE32291

Bale ramp - Spring loaded - BE32284

BaleTrak Pro monitor LESS mounting brackets (order if second monitor is desired) - BE32448

Drawbar Shield - BE32262

The rearview mirrors mount to the tractor cab to improve rearward visibility.

Gathering wheels

Gathering wheelsGathering wheels aid in picking up extra-wide or wind-scattered windrows.

Gathering wheels are side mounted and spring loaded.

NOTE: Gathering wheels are not available for MegaWide™ pickups.

High-moisture kit

High-moisture kitThis kit is for use when baling high-moisture crops.

Roll scrapers, mountings, and a staggered belt roll with anti-buildup spirals reduce wrappage and crop buildup.

High-moisture kit

High-moisture kitThis kit is for use when baling high-moisture crops.

Roll scrapers, mountings, and a staggered belt roll with anti-buildup spirals reduce wrappage and crop buildup.

Hitch Kit for 2 In. Thick Tractor Drawbar - AE57344

Implement Warning Lights - TY16055

Lacer vice

Lacer viceUse the lacer vice for repairing failed clipper-style belt splices or for splicing broken belts. When properly used, it will allow tight, even spacing of hooks when repairing belts.

It replaces the correct number of hooks in the belt in one operation. (Order through Parts.)

Order the following mounting bracket bundles to install BaleTrak Pro monitors in tractors with or without cabs.

PTO Driveline, 1-3/4 In. 1000 RPM Telescoping Tractor Hookup with Slip Clutch - BE32182

PTO Driveline, 1-3/8 In. 1000 RPM Telescoping Tractor Hookup with Slip Clutch - BE32186

PTO Driveline, 540 RPM Telescoping Tractor Hookup with Slip Clutch - BE32185

Pickup Gauge Wheels, Right and Left - BE31145

Safety chain for towed equipment, 9071.8474 kg (20,000 lb) - BE24261

Use the sidesheet enhancement kit in extremely abrasive crops and field conditions to add additional service life to 7 or 8 Series Round Balers with worn side sheets.

4-ft-wide auger kit (shield removed for photo)

4-ft-wide auger kit (shield removed for photo)In very dry, fluffy crop conditions, this auger kit prevents crop from climbing the front of the baler belts on 458 Standard, 458, and 468 Balers.

Located on top of the front staggered belt roll, the auger is chain-driven.

This auger kit is not a replacement for the high-moisture baling kit.

Variable core for balers with BaleWatch

Variable core for balers with BaleWatchThis variable core kit is for 457, 457 Silage Special, and 557 Balers equipped with the BaleWatch™ monitor.

Variable core for BaleTrak Plus or BaleTrak Pro

Variable core for BaleTrak Plus or BaleTrak ProThis variable core kit is for 67 Series Balers and 57 Series Balers equipped with the BaleTrak™ Pro and BaleTrak Plus monitor-controller.

This kit reduces hydraulic pressure for easier bale starts in difficult conditions.

- Reduces core density

- Adjustable soft core diameter to within 4 in. of the bale's outer diameter

- Controlled and adjusted from the BaleTrak Pro monitor-controller and BaleTrak Plus monitor-controller on 457 Silage Special, 457, 557, 466 Silage Special, 466, and 566 Round Balers

- Connects to a three-terminal convenience outlet on 457, 457 Silage Special, and 557 Round Balers, if equipped with an optional hydraulic tie and a BaleWatch monitor

Variable core valve - BE32298

Pickup

Pickup filler plates installed on baler

Pickup filler plates installed on baler

Pickup filler plates are designed to prevent corn cobs from becoming lodged in the pickup strippers. This attachment will improve pickup tooth and rotor tine reliability.

Pickup filler plates

Pickup filler plates

Utilization of the corn cob filler plates will greatly improve machine reliability in crops with high concentrations of cobs and will not adversely affect machine performance in other crop conditions.

NOTE: Not Compatible on the MegaWide™ High Capacity and Cutting (HC2) feed system.

Hydraulic pickup lift with down stop - BE32241

Hydraulic pickup lift with down stop - BE32240

Regular Pickup Gauge Wheel kit - BE31133

Power Take-off (Pto) Driveline

Power take-off (PTO) driveline, 34.925-mm (1 3/8-in.) 1000 rpm telescoping tractor hookup with cam clutch - BE32287

Power take-off (PTO) driveline, 34.925-mm (1 3/8-in.) 1000 rpm telescoping tractor hookup with slip clutch - BE32271

Power take-off (PTO) driveline, 44.45-mm (1 3/4-in.) 1000 rpm telescoping tractor hookup with slip clutch - BE32272

Power take-off (PTO) driveline, 540 rpm telescoping tractor hookup with cam clutch - BE32286

Power take-off (PTO) driveline, 540 rpm telescoping tractor hookup with slip clutch - BE32270

Side-sheet Enhancements

Use the sidesheet enhancement kit in extremely abrasive crops and field conditions to add additional service life to 7 or 8 Series Round Balers with worn side sheets.

Silage Special Kits

Silage special kit - 1.2192-m (4-ft.) wide - BE32442

Silage special kit - 1.524-m (5-ft.) wide - BE32443

Surface Wrap

Premium b-wrap kit - BE32551

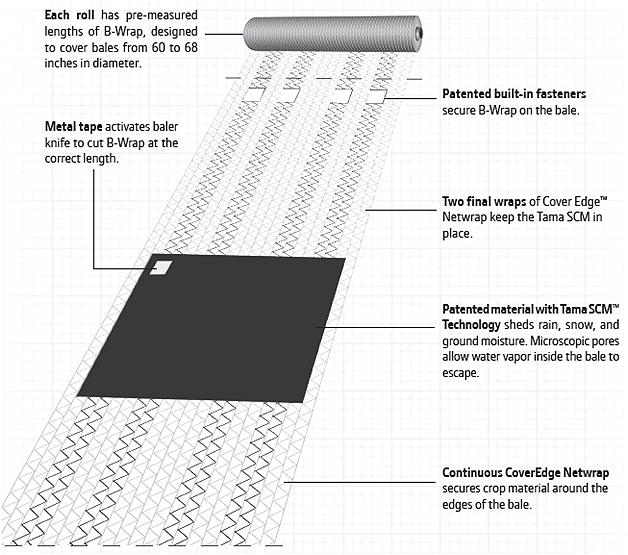

B-Wrap protects bales from rain, snow, and ground moisture

B-Wrap protects bales from rain, snow, and ground moisture

B-Wrap is applied onto bales just like net wrap, but it protects hay much better than net. B-Wrap includes a special patented material with Tama SCM Technology. It sheds rain and snow while protecting the bale from ground moisture. Plus this material has microscopic pores that let water vapor inside the bale escape. B-Wrap is the alternative to indoor storage, delivering barn-quality hay without the barn.

B-Wrap protects bale quality in all types of crops. Use B-Wrap on top quality hay, as well as straw, peanut hay, and corn stalks.

The B-Wrap kit is simple and can be dealer-installed in the field

The B-Wrap kit is simple and can be dealer-installed in the field

The B-Wrap kit is easy to install. The kit includes wiring that connects a sensor to the bale monitor and a new EPOM chip is also added to the bale monitor.

The B-Wrap kit is available for 459, 459 Silage Special, 559, 559 Silage Special, 469, 469 Silage Special, 569, and 569 Silage Special Round Balers.

This kit also works on these 7 and 8 Series Round Balers equipped for netwrap: 457, 457 Silage Special, 467, 467 Silage Special, 557, 567, 458, 458 Silage Special, 468, 468 Silage Special, 558, and 568 Round Balers. (7 and 8 Series Balers must be equipped with a speed compensation/slip clutch alert kit (BE32317). This speed compensation kit was standard equipment on some later 8 Series Balers. Balers with this kit have sensors on the slip clutch.)

A roll of John Deere B-Wrap

A roll of John Deere B-Wrap

A roll of B-Wrap looks and weighs similar to a roll of net, and B-Wrap loads into John Deere round balers exactly like net.

B-Wrap is designed for bales 60- to 68-in. in diameter. A roll of B-Wrap for 5-ft balers has 35 premeasured portions, enough to wrap exactly 35 bales. A roll of B-Wrap for 4-ft balers will wrap exactly 45 bales.

Balers with the B-Wrap attachment can switch between net wrap or B-Wrap

Balers with the B-Wrap attachment can switch between net wrap or B-Wrap

B-Wrap works in round balers much like net wrap. The B-Wrap kit allows a baler to use either B-Wrap or net. Switching between net and B-Wrap will take less than five minutes. Simply switch rolls, properly thread the new wrap into the baler, and then change bale monitor settings.

Here’s how B-Wrap works in the baler. When a bale reaches the maximum size programmed into the monitor, the operator stops forward travel and wrapping begins. The first length of B-Wrap is John Deere COVER-EDGE™ Net Wrap. John Deere COVER-EDGE goes right over the edge or the bale, pulling in loose crop material, giving the bale a solid, weather-resistant shape.

The next length of B-Wrap includes the patented material with Tama SCM technology. It sheds rain and snow, and protects bales from ground moisture. The final length covering a bale is two more wraps of John Deere COVER-EDGE Net. This securely holds the weather resistant Tama SCM in place.

Roll of B-Wrap showing the net wrap and patented material

Roll of B-Wrap showing the net wrap and patented material

Metal tape on the SCM activates the knife, cutting the B-Wrap at exactly the predetermined length. The

operator then backs the baler up about 10 feet and ejects the bale. Built-in fasteners keep B-Wrap in place during storage.

Built-in fasteners secure B-Wrap to the bale

Built-in fasteners secure B-Wrap to the bale

Limitations of B-Wrap:

- While B-Wrap does allow moisture inside the bale to escape, baling hay too wet will cause mold to form. B-Wrap is for dry hay only. Operators should bale hay at the same moisture level they would when using net.

- B-Wrap can dramatically reduce bale damage caused by ground moisture, but bales must be stored in a well-drained location.

To make sure the seam of the Tama SCM is in the proper location, bale kickers and bale ramps must be deactivated. The bale operator must back up about 10 feet before ejecting a B-Wrap bale. - B-Wrap does cost more per bale than net wrap, but it protects feed value much better. Users report that hay and straw looked and smelled like the day it was baled, even after a winter stored outside.

- B-Wrap is only available initially with a standard kit. The standard kit (BE32467) requires the operator to shut off the PTO with each bale.

- Full production available in US and Canada for 2014.

Twine Wrap

Adjustable twine guide

Adjustable twine guideAdjustable twine guides are used to move the location of the twine closer to the center of the bale.

- Especially useful when baling slick grasses and straw

- One left-hand adjustable twine guide is available for the 447, 457, and 457 Silage Special Balers

- Both a left-hand and right-hand adjustable twine guide are available for the 547 and 557 Balers

Wheels And Tires

XL tire

XL tireThe 21.5-16.1 XL high-flotation tires may be installed on balers equipped with a MegaWide™ or MegaWide Plus pickup to improve ride and decrease ground compaction.