5100E UTILITY TRACTOR

Utility Tractor

- John Deere PowerTech™ Diesel Engine with FT4 emissions compliance

- Cab or open operator station available

- Standard 12F/12R PowrReverser™ Transmission and MFWD

- 540/540 Economy PTO

View Product Brochure

Features

The U.S. EPA and Environment Canada requires all off-road diesel engines with 18.6 kW (25 hp) or more to meet stringent FT4 emissions regulations. John Deere uses the most efficient and cost effective solution for the tractor package to meet emissions requirements at each horsepower level. The 5M delivers a hassle-free emissions solution that allows faster work speeds and operation with ease.

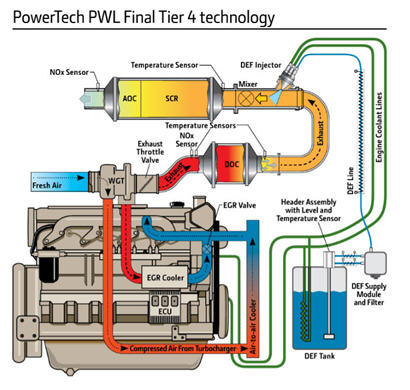

The engine powering the 5E is EPA-certified Tier Level 4. This is achieved through a combination of a diesel oxidation catalyst (DOC) and a selective catalyst reduction (SCR) using diesel exhaust fluid (DEF, or urea).

Several defining features on the 5E maximize the performance and reliability of the emissions package. A completely shielded DOC/SCR not only protects essential components from damage but also keeps out dirt and debris. The well-packaged and tightly organized circulation system means there is more room to work around the tractor.

PowerTech™ PWL Final Tier 4 engine technology

PowerTech™ PWL Final Tier 4 engine technologyKey components of the emissions system include:

DOC

Deere has chosen to utilize an exhaust filter (DOC) to reduce particulate material so the engine can operate at a level which produces less nitrogen oxide (NOx). With less NOx created, it requires less DEF to treat. The result is improved total fluid economy (diesel and DEF).

The engine is programmed to aggressively respond to changes in power needs, which can temporarily increase particulate matter. Since the exhaust filter removes particulate matter instead of the engine, the engine is left free to do what it is designed to do – deliver all of the power, torque, plus transient response needed at the exact moment needed.

DEF

DEF is an ISO 22241 standard aqueous urea solution consisting of 32.5 percent urea and has a freezing point of -11° C (12° F). A DEF tank keeps the operator in the field longer even when the temperatures drop below freezing. The DEF tank header is integrated with a temperature sensor and plumbed engine coolant lines are used to promote thawing and prevent freezing in the tank during operation.

DEF tank

DEF tankMounted near the DEF tank, the engine control unit (ECU)-controlled supply module draws diesel exhaust fluid from the storage tank and provides a pressurized flow to the dosing module. When the ignition key is off, the supply module pump will reverse direction to return any accumulated fluid back to the tank. The supply module is also fitted with a replaceable filter to prevent contaminants from entering the dosing lines. Both the supply module and dosing lines are electrically heated and controlled by the ECU to determine when diesel exhaust fluid dosing can begin.

The dosing module is cooled by engine coolant and used to inject DEF at a pressure of 900 kPa (130 psi) into the decomposition tube. A harness is connected to the dosing valve that relays the needed DEF to inject based upon the amount of NOx exiting the DOC measured from the NOx tube sensor.

The decomposition tube is the internal mixing device used to circulate DEF with engine exhaust prior to entering the SCR/AOC after-treatment device.

SCR

To reduce the NOx, DEF, or urea, is injected into the exhaust stream. When the exhaust gases combine with the DEF in the SCR catalyst, the NOx is broken down into nitrogen and water vapor.

Shielded for protection

Shielded for protectionExhaust gas recirculation (EGR)

How EGR works

EGR reduces the high temperatures where these compounds are formed in the engine cylinders by replacing excess oxygen with a prescribed amount of cooled exhaust gas.

Exhaust gases contain more carbon dioxide than oxygen. The EGR valve, in conjunction with the venturi tube, and ECU, allow a controlled amount of exhaust gas to enter the intake manifold to mix with the incoming fresh air.

Replacing excess oxygen with cooled exhaust gas leads to:

- Lower combustion temperatures, creating less NOx.

In addition, EGR allows for:

- Advanced timing

- Optimal engine performance

- Maximum fuel economy

For added performance and efficiency, the engine passes the exhaust gases through an EGR cooler before it enters the engine.

Exhaust airflow enters into the EGR cooler from the exhaust manifold near the turbocharger. Based on engine load, air temperatures, and rpm, the engine control unit (ECU) opens or closes the EGR valve, allowing a measured percentage of exhaust gas to enter the intake manifold. The gases mix with the rest of the incoming air from the turbocharger and aftercooler before entering the cylinders.

Series turbochargers

The PowerTech PWL 4.5L (274.6-cu in.) engine utilizes one turbocharger — a fixed geometry turbocharger. Fresh air is first drawn into the low-pressure fixed geometry turbocharger and compressed to a higher pressure. The compressed air is then routed to the charge air cooler and then to the intake manifold.

Benefits of air-to-air aftercooling:

- Lowers the intake manifold air temperature

- Provides more efficient cooling while reducing temperatures for greater engine reliability

- Higher volume of air flows into the cylinders

- Engine is capable of meeting the increasing horsepower demands

Combustion process with externally cooled EGR:

Functions:

- According to engine operating conditions, the recirculated exhaust gases reduce the oxygen portion in the intake air to approximately 20 percent. Without any increase of the charge air pressure, the oxygen rate is not high enough to ensure a complete combustion of the fuel injected at high engine loads.

Advantages:

- Fuel-efficient combustion is achieved, because sufficient oxygen is provided.

A restrained, cooler combustion is realized, since the typical hot combustion process, which is generated by an oxygen surplus, is dampened by the inert exhaust gases. NOx emissions are reduced.

For more information regarding EPA regulations and the technology behind John Deere Integrated Emissions Control systems please visit the following link:

https://www.deere.com/en/engines-and-drivetrain/final-tier-4-stage-iv/

|

4-cylinder 5E torque curve summary

4-cylinder 5E torque curve summaryThis PowrReverser transmission provides 24 forward speeds and 12 reverse (24F/12R) speeds. This transmission comes standard with a dual speed 540/540 Economy power take-off (PTO), and it is ideal for applications requiring frequent directional changes, such as loader work and PTO work like rotary cutting and baling hay.

Hydraulic wet forward and reverse clutches maximize durability and outlast the life of any dry clutch. When tractors are run by multiple operators with a variety of experience levels, a wet clutch is the best way to maintain transmission integrity and performance while decreasing clutch replacement costs.

Two platform-mounted levers offer easy and comfortable shifting. To distinguish the two levers for ease of operation, the gear-shift lever is longer and the less-used range lever is shorter. Unique knobs make it easy to distinguish between the two just by feel.

The hi/lo selector buttons are located on the gear shift lever for each forward gear, and are represented by a rabbit and a turtle respectively.

The forward lever selects one of four gears. All are synchronized for on-the-go shifting with the use of the clutch. The rear lever selects one of three ranges: A, B, or C.

Gear shift lever with hi/lo buttons

Gear shift lever with hi/lo buttonsMaximum productivity is achieved with clutch-less hydraulic shifting between forward and reverse. PowrReverser functionality is ideal for rear blading and any applications that require frequent directional changes in tight spaces. An electrohydraulic fingertip directional lever control allows the operator to effortlessly switch directions with a small finger motion. The control is located on the left side of the instrument console and selects forward, reverse, and neutral positions. It also allows the operator to steer and shift direction with the left hand, freeing the right hand to operate other tractor controls, such as the loader, rear implements, or hand throttle. The PowrReverser has a built-in engagement override valve for additional safety. This valve requires the clutch pedal to be depressed one time after each engine start before the transmission will begin to operate normally, giving the operator another opportunity to put all focus on the tractor.

A neutral start switch requires the directional lever be in the neutral position to start the engine.

Left-hand reverser lever

Left-hand reverser leverThe speed of directional changes can be adjusted to the operator's preference or application demands with an optional field installed infinitely variable control kit.

24F/12R transmission includes:

- Wet clutch

- Platform-mounted shift levers with four gears (with hi/lo selector in forward) and three ranges

- Left-hand reverser

- Constant-mesh helical-cut gears

- Pressure-lubricated top shaft

- Positive park pawl

- Neutral start switch

All tractors have economy PTO (E-PTO), a fuel-saving feature which allows customers to operate rear implements at 540 PTO rpm but at lower engine rpm. The result is lower engine vibration, reduced noise, less wear and tear on the engine, reduced fuel consumption and increased operator comfort.

See the PTO functional area for more information on E-PTO.

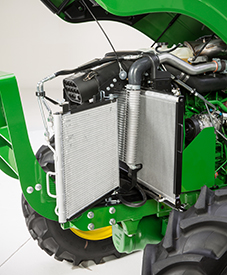

Every utility tractor producer wants to maximize uptime and appreciates enhanced performance. The cooling package on the Final Tier 4 (FT4) 4-cylinder 5E Tractors allows for easier access to and serviceability of certain critical components. This improvement to serviceability will save time and also enhance tractor performance.

The cooling package features a first-pass screen to catch larger debris, a slide-out condenser (only on cab tractors) a charge air cooler that tilts forward, and a hydraulic oil cooler that slides out halfway to both sides of the tractor.

First pass screen

First pass screen Slide out condenser on cabs

Slide out condenser on cabs Charge air cooler tilted forward

Charge air cooler tilted forwardThe engine is equipped with an electronically controlled fan drive, which means that it only runs as fast as the needs of the tractor demand at that time. This is a fuel-saving device which improves hydraulic cooling and reduces the noise level for the operator. It also positively impacts total fluid efficiency.

Producer needs drive John Deere to deliver distinctive value in product solutions. The applications in which John Deere utility tractors, implements, and attachments are used are growing by the day. A 540/1000 PTO rpm field-installed kit is available for the 5E Tractors. With this kit installed, operators can switch between standard 540 or 1000 PTO rpm based on the requirements of the implement. From rotary cutting, to shredding to snow throwing and baling, the capability to operate an implement requiring 1000 rear PTO rpm is available.

Once installation is complete, this solution offers the convenience of switching between 540 and 1000 PTO rpm with relative ease. Combined with the dry sump design, this attachment includes a reversible shaft. This provides for a less mess, no stress option that will enhance customer productivity and increase uptime.

540/1000 PTO rpm field-installed kit

540/1000 PTO rpm field-installed kitAn instrument cluster provides more information in a cleaner, more vibrant display. The roll-mode function has the ability to show more diagnostic codes to keep the operator informed about the tractor’s functionality.

This window into tractor functionality and diagnostics provides ample information. Indicators, warning lights, and even gauges are clear and bright. The roll-mode function now provides operators with crucial onboard diagnostics. Engine hours, power take-off (PTO) speed, ground speed, hi-lo indicator, forward, neutral, and reverse are all visible at the same time. There is a light-out indicator for trailer light, turn light, and hazard light bulbs which is driven by updated software. It is a straightforward layout and sleek design with no customer interface required. When operating the PTO, there are clearly presented PTO target bars to indicate the correct PTO speed.

Instrument cluster lights

Instrument cluster lightsThere are daytime and nighttime modes which are based on the position of the light switch. The mode adjusts the backlight levels of the display for optimum visibility.

Specifications

Compare the specifications of up to 4 models

| Key Specs | 5100e-utility-tractor Current Model |

|---|---|

| Engine description | John Deere PowerTech 4045 |

| Engine displacement | 4 cylinders: 4.5 L 276 cu in. |

| Rated engine power | At 2400 per ISO 97/68/EC: 74.6 kW 100 hp |

| Rated PTO power (hp SAE) | At 2400 per SAE: 63.4 kW 85 hp |

| Maximum PTO power | |

| Transmission type | Standard: 12F/12R PowrReverser Optional: 24F/12R PowrReverser |

| Hydraulic pump rated output | 85.1 L/min 22.5 gpm |

| Rear hitch category (SAE designation) | Category 2 |

| Base machine weight | |

| Maximum engine power | |

| Engine specifications | |

| Description | John Deere PowerTech 4045 |

| Engine type | |

| Engine family | EJDXL04.5211 |

| Rated speed | |

| Aspiration | Turbocharged |

| Cylinders liners | Wet sleeved |

| Emission level | |

| After treatment type | |

| Displacement | 4 cylinders: 4.5 L 276 cu in. |

| Engine performance | |

| Rated power | At 2400 per ISO 97/68/EC: 74.6 kW 100 hp |

| Rated PTO power (hp SAE) | At 2400 per SAE: 63.4 kW 85 hp |

| Maximum PTO power | |

| Power boost | |

| Engine peak torque | |

| PTO torque rise | |

| Intelligent Power Management (available in transport and/or mobile PTO applications) | |

| Maximum engine power | |

| Transmission | |

| Type | Standard: 12F/12R PowrReverser Optional: 24F/12R PowrReverser |

| Reverser | Yes |

| Clutch; wet/dry | Wet |

| Creeper | Not available |

| Hydraulic system | |

| Type | Open center |

| Pump rated output | Standard: 85.1 L/min 22.5 gpm |

| Available flow at a single rear SCV | 60.1 L/min 15.9 gpm |

| Available flow at front SCVs | |

| Number of rear selective control valves (SCVs) | 2; up to 3 |

| Number of mid selective control valves (SCVs) | 2; up to 3 |

| Number of front selective control valves (SCVs) | |

| Joystick SCV control | Optional |

| SCV control | |

| Rear hitch | |

| Hitch draft control load sense type | Mechanical |

| Remote control valves available | 2; up to 3 |

| Hitch category (SAE designation) | Category 2 |

| Maximum lift capacity behind lift points | Standard: 1457 kg 3213 lb |

| Sensing type | Top link |

| Rear axle differential lock | |

| Lift capacity at standard frame | |

| Drawbar | |

| Drawbar category | |

| Maximum vertical load | |

| Rear power take-off (PTO) | |

| Type | Standard: 540/540E Optional: 540/1000 |

| Engine rpm (at rated PTO speeds) | 540 at 2400 rpm 540E at 1716 rpm 1000 at 2400 rpm |

| PTO actuation | Electrohydraulic |

| Ground speed PTO option availability | |

| Multispeed PTO option availability | |

| Front hitch | |

| Category | |

| Electric power | |

| Standard lift capacity | |

| Front power take-off (PTO) | |

| PTO speed | |

| Rear axle | |

| Type | Inboard planetary |

| Final drive type | |

| Differential controls | Mechanical (pedal) |

| Axle type | Flanged |

| Brakes, type and control | Hydraulic wet disc |

| Rear differential lock | |

| Load rating | |

| Front axle | |

| Type | |

| Front axle differential lock | |

| Load rating | |

| Tires | |

| Front | MFWD: 12.4-24 R1 |

| Rear | MFWD: 18.4-30 R1 |

| Wheel tread range | MFWD: front: 1340-1904 mm 52.8-75.0 in. |

| Turning radius with brakes | MFWD: 3.54 m 11.6 ft |

| Turning radius without brakes | MFWD: 4.36 m 14.3 ft |

| Steering | |

| Type | |

| Electrical system | |

| Alternator size | |

| Battery options | |

| Total cold cranking amps | |

| Type of bulb in beacon (Halogen, Zenon, LED) | |

| Type of bulb in headlight (Halogen, Zenon, LED) | |

| Working lights | |

| dB(A) rating for backup alarm | |

| Operator station | |

| Rollover protective structure, OOS | Rigid - foldable - telescopic Foldable, 2-post Platform - flat/straddle Straddle Gearshift location - console/floor Floor |

| Seat | |

| Cab suspension | |

| Instructional seat | |

| Display | |

| Radio | |

| Inner cab volume | |

| dB(A) rating | 78 dBA |

| Cab glass area | |

| Front visibility | |

| Safety glass rating | |

| Dimensions | |

| Wheelbase | MFWD: 2350 mm 92.5 in. |

| Overall length | |

| Drawbar clearance | |

| Front axle center | |

| Approximate shipping weight, Open;Cab | MFWD: Open: 3300 kg 7275 lb Cab: 3700 kg 8150 lb |

| Overall height | |

| Weight | |

| Base machine weight | |

| Maximum ballast level | |

| Maximum permissible weight | |

| Capacities | |

| Crankcase oil volume | |

| Fuel tank | Standard: Open: 94.6 L 25 U.S. gal. Cab: 114 L/min 30 U.S. gal. |

| Diesel exhaust fluid (DEF) tank | |

| Cooling system | |

| Transmission-hydraulic system | |

| Serviceability | |

| Interval for engine oil change | |

| Interval for hydraulic/transmission oil change | |

| Interval for engine coolant change | |

| Loaders | |

| Loader | |

| Lift capacity at full height | |

| Maximum lift height | |

| Precision AG | |

| Guidance | |

| Telematic | |

| Remote diagnostics | |

| Miscellaneous | |

| Country of manufacture | Augusta, GA (USA) |

| Side slope rating | |

| Uphill/downhill slope rating | |

| Tracks | |

| Drive type | |

| Midrollers | |

| Track width | |

| Tread spacing |

Accessories and Attachments

Alternator

Backup Alarm

For those who require an alarm in reverse speeds to satisfy safety regulations and governmental bid requirements, this alarm is rear mounted and designed to provide optimum clearance from the 3-point hitch.

The beacon light kit is for the operator who is required to meet certain requirements for government and commercial applications. The beacon light is not compatible with open operator station (OOS) tractors.

The kit consists of a rotating, high-intensity light that rests inside an amber-colored safety lens. A cab interior roof-mounted rocker switch controls turning on and off the light.

Beacon Lighting

Cab Equipment

Telescopic mirror mounted on 5020 Series Cab

Telescopic mirror mounted on 5020 Series Cab Telescopic mirror mounted on 5M Open Station

Telescopic mirror mounted on 5M Open StationTelescopic rearview mirrors provide operators with a wide rear view of the field or road. These mirrors are especially useful when towing wagons or large implements.

The mirrors are adjusted manually and telescope.

NOTE: If mounting mirrors on the 5M Open-Station Tractors, one RE244177 rearview mirror mounting kit is needed for each side.

Telescopic mirror mounted on 5020 Series Cab

Telescopic mirror mounted on 5020 Series Cab Telescopic mirror mounted on 5M Open Station

Telescopic mirror mounted on 5M Open StationTelescopic rearview mirrors provide operators with a wide rear view of the field or road. These mirrors are especially useful when towing wagons or large implements.

The mirrors are adjusted manually and telescope.

NOTE: If mounting mirrors on the 5M Open-Station Tractors, one RE244177 rearview mirror mounting kit is needed for each side.

Cab Instructional Seat

Cab Operator's Station

Cell phones, tablets, and other devices are key tools for farming today. John Deere has now made it easier than ever to incorporate these tools into the operator's station.

Stay connected with the RAM® cell phone and tablet mounts. John Deere offers a vast selection of adjustable accessory mounting solutions and media devices to fit every need and application.

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mountRAM is a trademark of National Products Inc.

Air-ride suspension kit

Air-ride suspension kitThe air-ride seat suspension provides vertical and horizontal seat suspension for maximum operator comfort in any terrain.

Key benefits include:

- Maximum ride comfort and quality, thus minimizing operator fatigue

- Dampens lower-frequency vibration better than mechanical suspensions

- Operator weight capacity is increased to 330 lb

- Close-out boot provides enhanced appearance

This kit includes air-ride seat suspension, adapter plate, close-out boot, and push pins. The cab is pre-wired for this kit. The kit does not include an actual seat, but rather the suspension kit replaces the mechanical standard suspension on the existing seat.

For cab tractors only.

Ashtray

Ashtray Cigarette lighter

Cigarette lighterCell phones, tablets, and other devices are key tools for farming today. John Deere has now made it easier than ever to incorporate these tools into the operator's station.

Stay connected with the RAM® cell phone and tablet mounts. John Deere offers a vast selection of adjustable accessory mounting solutions and media devices to fit every need and application.

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mountRAM is a trademark of National Products Inc.

Ashtray

Ashtray Cigarette lighter

Cigarette lighter Powerstrip in 5025 Series Cab Tractor

Powerstrip in 5025 Series Cab TractorA powerstrip provides the operator with an additional six outlets providing key-switched and unswitched power that works simply by rotating the position of the plug 180 degrees.

Right Hand Door Kit (CAB ONLY) - BSJ10264

A favorite worldwide, the RAM self-leveling cup holder is now available as a kit - designed specifically for Deere equipment. It is easily installed to keep your favorite beverage upright even in the roughest terrain. The perfect accessory for any cab that has 10-mm mounting bosses.

Self-leveling cup holder John Deere branded beverage insulator included

Self-leveling cup holder John Deere branded beverage insulator included

The new cup holder features a unique self-leveling design. This pivoting design allows easy adjustment for the holder while offsetting motion of the vehicle when moving.

Features and applications:

- Self-leveling action reduces spills

- Durable design for rough environments

- Easy adjustable mounting for ideal placement

- Includes John Deere branded beverage insulator

- Compatible with most monitor brackets and all 10-mm threaded bosses

Single horn kit - LVB26096

Cold Weather Packages

Drawbar

The heavy-duty drawbar adds durability to tractors pulling drawn implements.

Exhaust

4-cylinder 5E Final Tier 4 (FT4) side exhaust

4-cylinder 5E Final Tier 4 (FT4) side exhaustThe field-installed side exhaust solution provides a low, horizontal exhaust position for producers operating in applications where a low exhaust point is required, such as orchards and poultry. This kit is available on the 4-cylinder 5E FT4 compliant standard tractors (5085E and 5100E) and is compatible with cab and open operator station tractors.

Front Axle

Axle extensions are required to achieve tread settings greater than 78.7 in. on eight-position wheels.

Front Fenders

mounting bracket

mounting bracketMounting bracket and hardware kits are available for front fenders. Fenders protect the operator and tractor from debris thrown by the front tires, especially when going from severe conditions to transport speeds.

The mounting bracket is not compatible with front loaders.

Front fenders installed on a 5M Tractor

Front fenders installed on a 5M TractorMechanical front-wheel drive (MFWD) front fenders protect operators and the 4WD tractor from debris thrown by the front tires, especially when going from severe conditions to transport speeds.

The fenders are not compatible with loaders. LVB25776 mounting bracket and hardware kit must be ordered separately.

Front fenders installed on a 5M Tractor

Front fenders installed on a 5M TractorMechanical front-wheel drive (MFWD) front fenders protect operators and the 4WD tractor from debris thrown by the front tires, especially when going from severe conditions to transport speeds.

The fenders are not compatible with loaders. LVB25776 mounting bracket and hardware kit must be ordered separately.

Front fenders installed on a 5M Tractor

Front fenders installed on a 5M TractorMechanical front-wheel drive (MFWD) front fenders protect operators and the 4WD tractor from debris thrown by the front tires, especially when going from severe conditions to transport speeds.

The fenders are not compatible with loaders. LVB25776 mounting bracket and hardware kit must be ordered separately.

Front Weights

Front weight support, R262449

Front weight support, R262449 Suitcase weights (non-5M support)

Suitcase weights (non-5M support)A front weight bracket can be installed to the front of the tractor when ballast is needed. The weight bracket weighs approximately 187 lb and Quik-Tatch weights can easily be added for additional weight. Add up to 10 front weights to the weight bracket.

NOTE: The front weight bracket is compatible with the hood and brush guards also installed.

See the ballasting and optimizing performance section or the tractor operator's manual for additional ballasting information.

Front weight support, R262449

Front weight support, R262449 Suitcase weights (non-5M support)

Suitcase weights (non-5M support)A front weight bracket can be installed to the front of the tractor when ballast is needed. The weight bracket weighs approximately 187 lb and Quik-Tatch weights can easily be added for additional weight. Add up to 10 front weights to the weight bracket.

NOTE: The front weight bracket is compatible with the hood and brush guards also installed.

See the ballasting and optimizing performance section or the tractor operator's manual for additional ballasting information.

Hood Guards

Hood guard for 5M Series Tractors

Hood guard for 5M Series TractorsThe heavy-duty hood guard is compatible with 5R Tractor series.

The basic function of a hood guard is to:

- Help protect the tractor grille and hood from falling debris or stationary objects such as a wagon or mixer

- Allow for lighting at night

The hood guard:

- Can be used with or without the tractor front weight bracket but not with the actual front weights while using the loader (this would overload the front axle)

It is highly recommended to purchase a front weight bracket when using a loader. The hood guard is designed to be slightly rearward of the front weight bracket. This is so the front weight bracket is the first point of contact against lower stationary objects.

The features of the hood guard include:

- Allow the hood to open and provide access to the battery and filter

- Extra steel behind the mainframe to increase strength

- High height to better protect the top of the hood

Hydraulics

Lighting

Rear work light

Rear work lightA 37.5-W halogen floodlight is adjustable and illuminates areas to the rear of the tractor.

The bulb can be easily replaced as needed.

Auxiliary work light kit (1) on front of a 5M cab

Auxiliary work light kit (1) on front of a 5M cab Auxiliary work light kit (2) on rear of a 5M Cab Tractor

Auxiliary work light kit (2) on rear of a 5M Cab TractorRound-halogen lights are roof mounted for additional lighting on the front and/or rear of a cab tractor. Each auxiliary work light kit contains lighting for the front or rear; two kits must be ordered for front and rear lighting.

Floodlamp/Work Lights, LED, (4 Lights) - BSJ10163

LED HEADLIGHTS - BSJ10325

LED ROPS mounted rear work lights - BSJ10478

Mid Selective Control Valves

3rd Function Mid Hydraulic Control Valve Kit (Converting Dual Mid to Triple Mid) - BSJ10105

Dual Mid Hydraulic Control Valve Kit with Joystick Control - BSJ10109

Mirrors

Telescopic mirror mounted on 5020 Series Cab

Telescopic mirror mounted on 5020 Series Cab Telescopic mirror mounted on 5M Open Station

Telescopic mirror mounted on 5M Open StationTelescopic rearview mirrors provide operators with a wide rear view of the field or road. These mirrors are especially useful when towing wagons or large implements.

The mirrors are adjusted manually and telescope.

NOTE: If mounting mirrors on the 5M Open-Station Tractors, one RE244177 rearview mirror mounting kit is needed for each side.

Miscellaneous

Implement hitch pins and bushings adapt Category 1 implements to fit a Category 2 3-point hitch.

Implement hitch pins and bushings adapt Category 1 implements to fit a Category 2 3-point hitch.

Offset drawbar

Offset drawbarOffset drawbars can be used with large- or small-diameter tires to raise or lower the drawbar height.

Straight drawbar clevis kit

Straight drawbar clevis kitThe offset drawbar clevis kit allows quick, no-hassle, safe hookups to many popular drawn implements.

Straight drawbar clevis kit

Straight drawbar clevis kitThe straight drawbar clevis kit allows quick, no-hassle, safe hookups to many popular drawn implements.

With loads of capacity, two removable shelves, and an innovative front door and lid design, this new tractor utility box breaks new ground for convenience, versatility, and rugged design. Grease guns, tow chains, hitch pins, and many other essential items can be stored safely and can be easily accessed, putting an end to cluttered cabs.

Front utility box

Front utility box Front utility box and bracket

Front utility box and bracketBuilt from welded, heavy-gauge sheet steel, this new box offers long-term durability not seen with other toolboxes. A heavy-duty gas strut on the lid and locking pins make opening and locking simple and easy.

Specifications:

- Made in the USA

- 23 in. x 8 in. x 12 in.

- Two removable shelves

- Heavy-duty construction

- Fold down front door for easy access

- Mount with existing R127764 tractor weights using BRE10153 bracket

- Mount on 9X30 Series Wheel Tractors (front left side) using BRE10291 bracket

With loads of capacity, two removable shelves, and an innovative front door and lid design, this new tractor utility box breaks new ground for convenience, versatility, and rugged design. Grease guns, tow chains, hitch pins, and many other essential items can be stored safely and can be easily accessed, putting an end to cluttered cabs.

Front utility box

Front utility box Front utility box and bracket

Front utility box and bracketBuilt from welded, heavy-gauge sheet steel, this new box offers long-term durability not seen with other toolboxes. A heavy-duty gas strut on the lid and locking pins make opening and locking simple and easy.

Specifications:

- Made in the USA

- 23 in. x 8 in. x 12 in.

- Two removable shelves

- Heavy-duty construction

- Fold down front door for easy access

- Mount with existing R127764 tractor weights using BRE10153 bracket

- Mount on 9X30 Series Wheel Tractors (front left side) using BRE10291 bracket

Axle extensions are required to achieve wider tread settings.

Axle extensions are required to achieve wider axle tread settings.

Axle extensions are required to achieve wider axle tread settings.

Safety Chain Support Kit - RE19428

For those concerned about the security of their cab tractor, a custom key is available.

Service Horn - AL203265

Open Operator's Station

Standard canopy

Standard canopy Deluxe canopy

Deluxe canopyThe canopy attaches to the open operator station rollover protective structure (ROPS).

The 1613.2-mm (63.5-in.) long, 1322.7-mm (52-in.) wide ABS canopy can offer protection to the operator from inclement weather and direct overhead sunlight.

NOTE: Additional mounting brackets are required to adapt the canopy (LVB25334) to ROPS. See ordering information below.

NOTE: Deluxe canopy (LVB25785) includes additional headliner and marker lights for select open station models and also requires LVB25332.

5M with standard canopy

5M with standard canopyMounting brackets and hardware bundles are required to adapt a canopy to the tractor rollover protective structure (ROPS).

Operator's Station

Cell phones, tablets, and other devices are key tools for farming today. John Deere has now made it easier than ever to incorporate these tools into the operator's station.

Stay connected with the RAM® cell phone and tablet mounts. John Deere offers a vast selection of adjustable accessory mounting solutions and media devices to fit every need and application.

Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mount Mounting bracket with cell phone and tablet mount

Mounting bracket with cell phone and tablet mountRAM is a trademark of National Products Inc.

Radio

Antenna - AL222926

Radio - AM/FM, Bosch (Standard) - RE567557

Rear Fenders

Rear Fender Extension Kit without Work Lights - BSJ10044

Rear fender extension on 5020 Series Tractor

Rear fender extension on 5020 Series TractorProtects the operator from debris.

Stationary fenders (Quik-Tatch)

Stationary fenders (Quik-Tatch)

Stationary fenders are fixed to the loader mounting frames and therefore do not pivot when the tractor tires turn.

Stationary fenders offer several key advantages over traditional fenders:

- The turning radius of the tractor is not reduced when a loader is installed

- Fenders can be used with the tallest tires with a loader at any tread setting

- Less fender damage occurs because the fender never becomes the widest part of the tractor when turning next to fences or walls

- The fenders can be easily removed to make servicing the tractor easier

- The height of the fender can be adjusted based on the height of the tire

- Mud coverage is not compromised

Rear Selective Control Valves

Rear Wheel Weights

Rear-wheel weight

Rear-wheel weightFor improved traction and/or ballast, 95-lb rear-wheel weights can be installed.

See the ballasting and optimizing performance section in the sales manual or the tractor's operator's manual for additional ballasting information.

Three-point Hitch

Quick-coupler

Quick-couplerThe second-generation iMatch™ quick-hitch allows a no-hassle attachment option for many integral implements such as box blades, rear blades, rotary tillers, and rotary cutters. The hitch is constructed of tubular and box-welded steel, and the bushings and hooks are heat-treated to prevent cracking for long wear life. Hardened, zinc-plated steel alloy pins take the shock of heavy loads and withstand exposure to the elements. Hitch locking handles rotate 100 degrees to open the locking lugs for easy implement release. The top link is adjustable for compatibility and versatility.

This attachment is only available through Parts.

Transmission

Modulation knob

Modulation knobChange the transition speed of the PowrReverser transmission with a simple dial located near the steering column. This knob is used to adjust modulation sensitivity.

Adjust the aggressiveness of the forward to reverse transition, for either a quick fast transition or a smoother, slower transition.